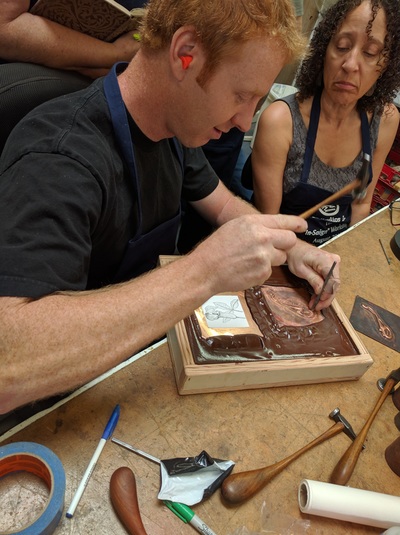

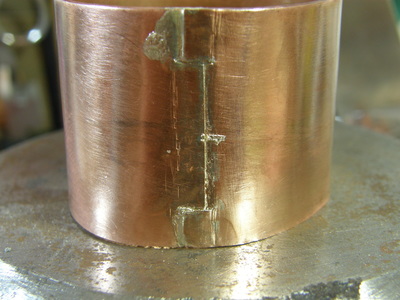

We started off by showing her how to use a snarling iron - this for when you need repousse on a vessel and it is too small to get your hands and tools inside - think cup, vase and such. I brought a cheapie copper cup that I got off of eBay for her to practice on.

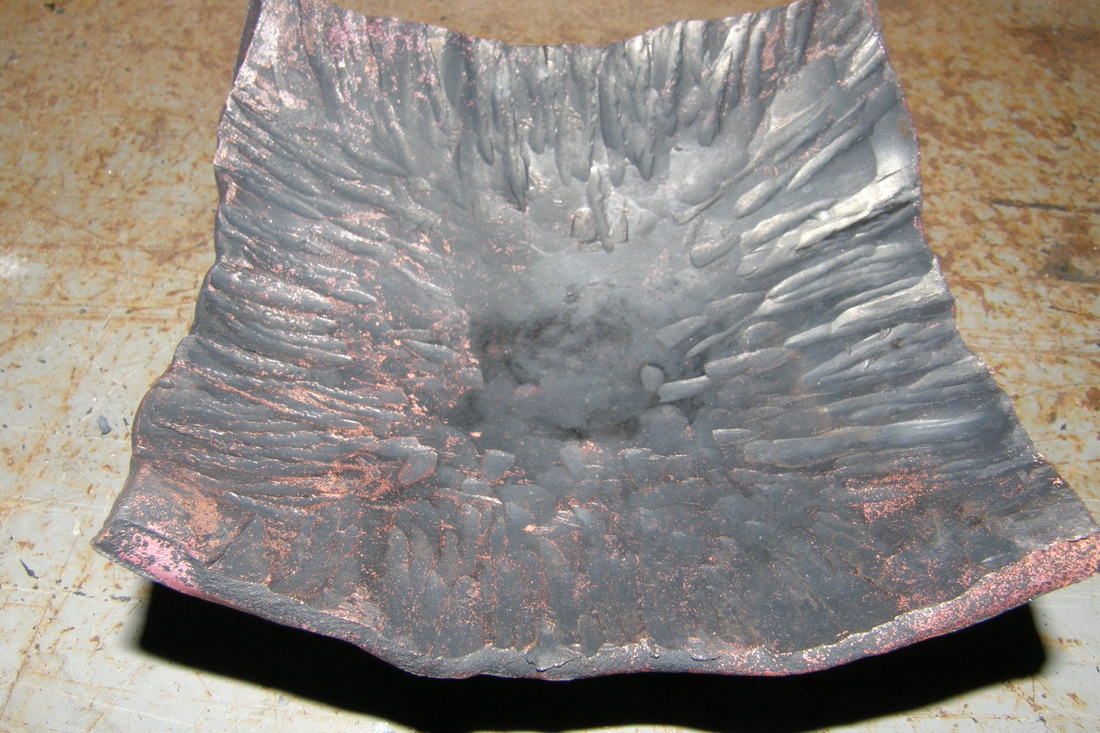

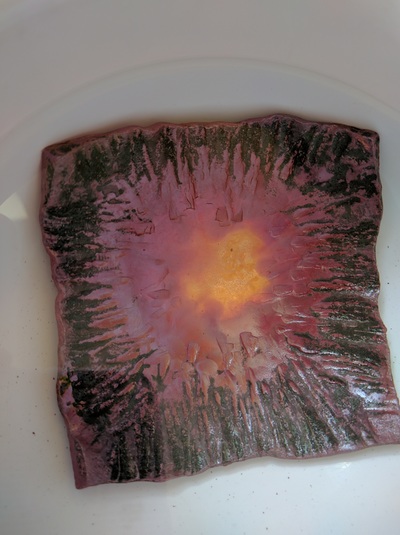

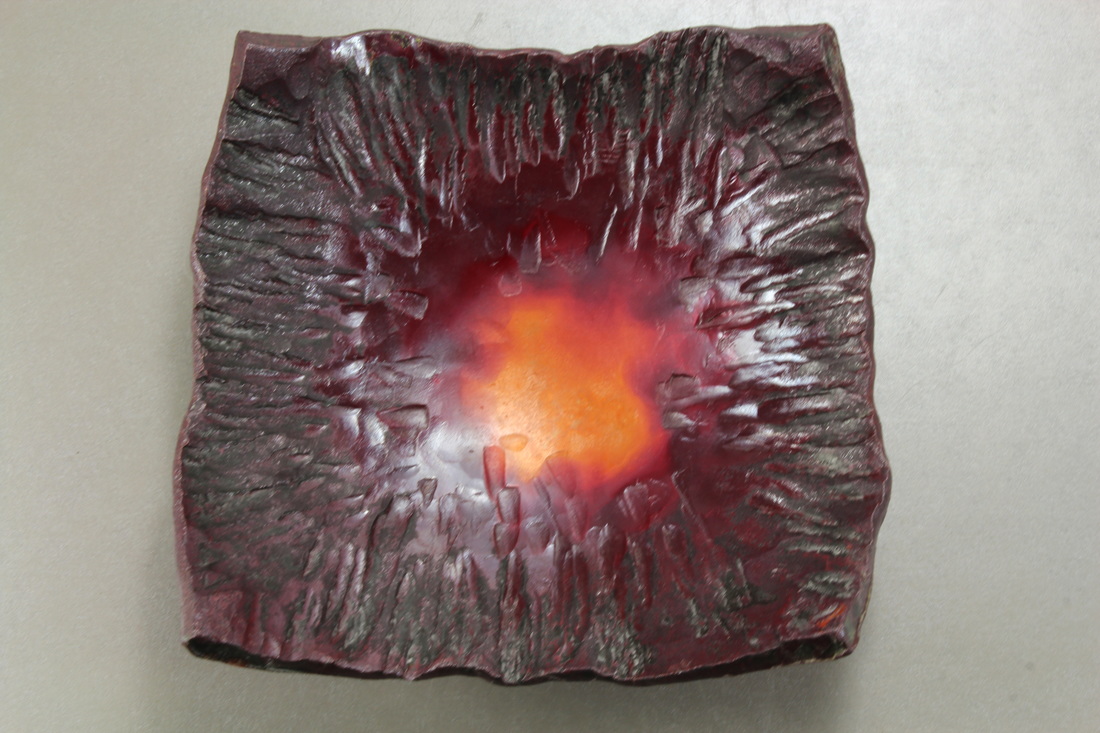

Then I showed her how to put a vessel into her pitch bowl so she could chase on it while still moving/rotating the vessel when moving on to the next section.

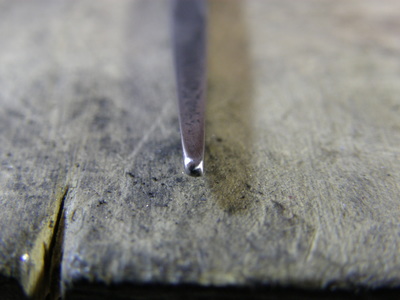

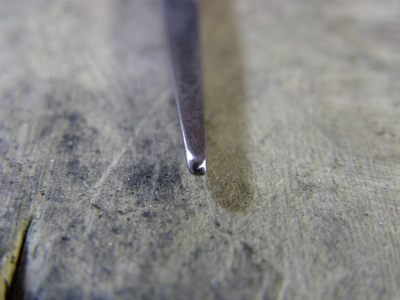

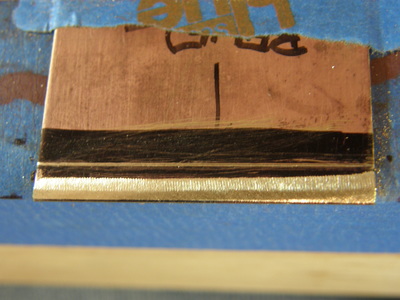

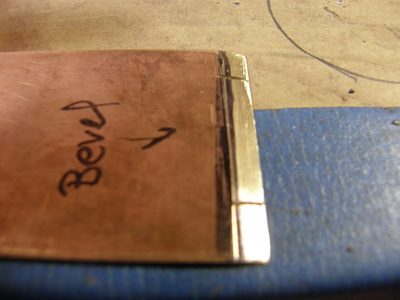

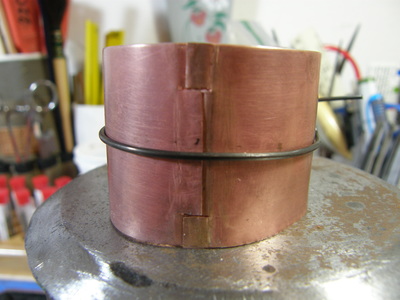

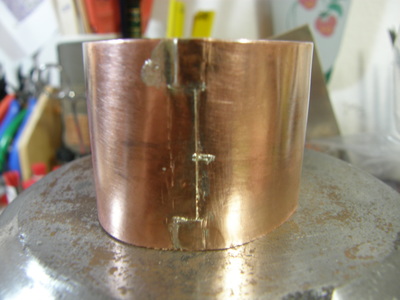

The last thing we worked on and spent most of our time on was FORGING! We started off with some basic exercises - different shaped hammers moving the metal in different directions; forging round stock (wire) into a square and a rectangle; and then tapers and cross tapers. Once that was done we made some large "jump" rings and forged some bangles. After Jan had the hang of it; I then pulled out some ..wait for it SILVER so she could make a forged bangle using a precious metal. It was her first time working in silver and to see her reaction, watch the small video below and then look at all the pictures I took.

RSS Feed

RSS Feed