During that time I survived the pandemic; retired from the 8-5 grind despite Engineers never really retiring; visited friends in Scotland I had not seen in 10 years and walked almost a hundred miles on the Speyside Way; got COVID; and then The Shop Elf passed away this past January.

My studio is a MESS and I will get to a complete re-org and cleaning of it later in October and November; the studio does not have A/C (nor heat) so right now it is quite warm in there.

So let me show you two things I have worked on yesterday and today.

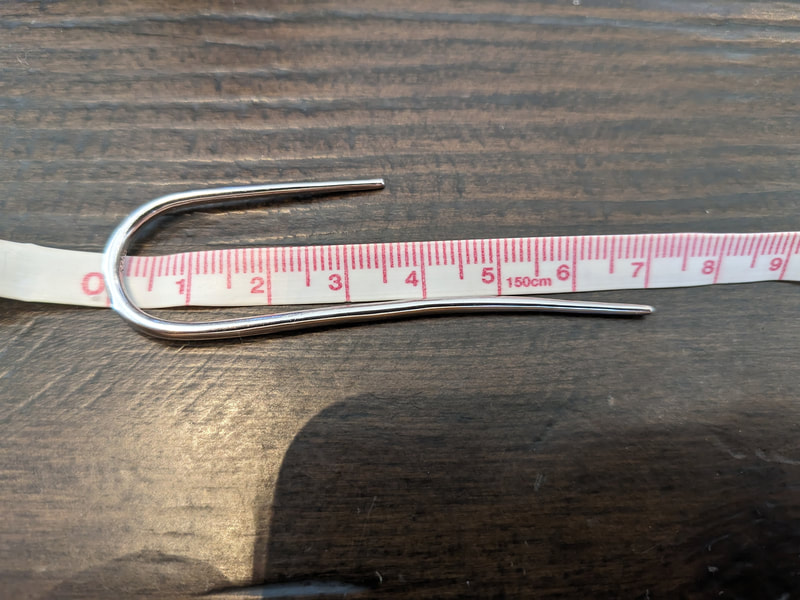

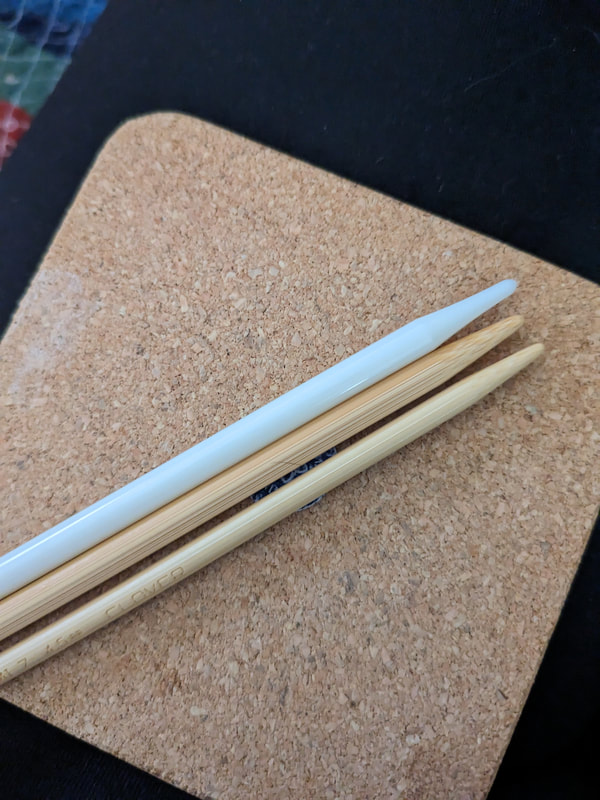

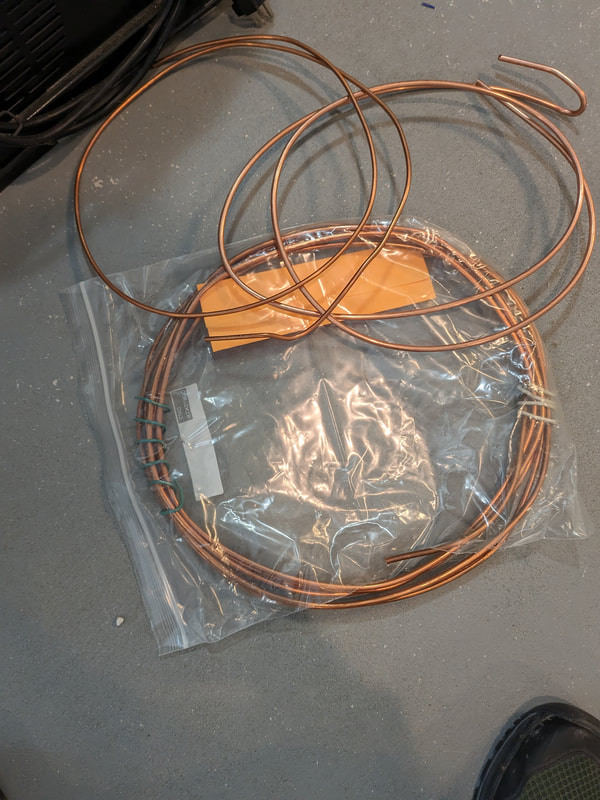

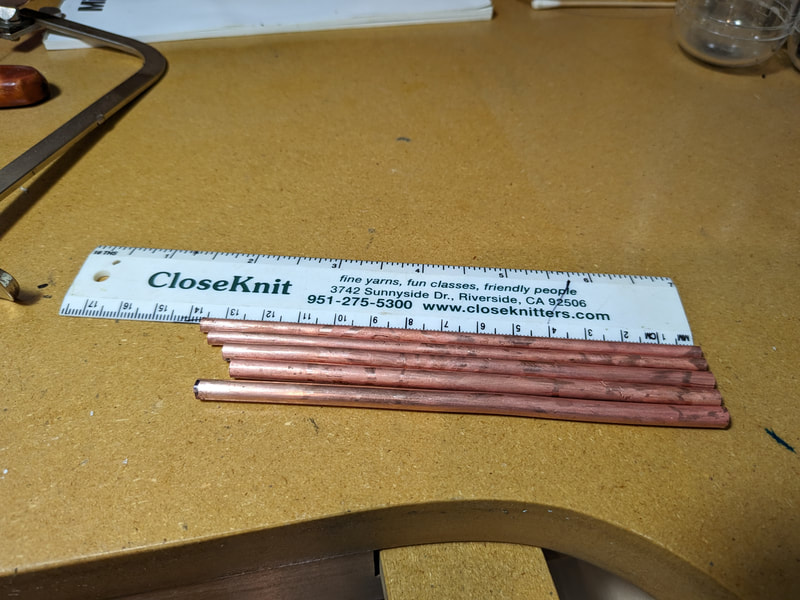

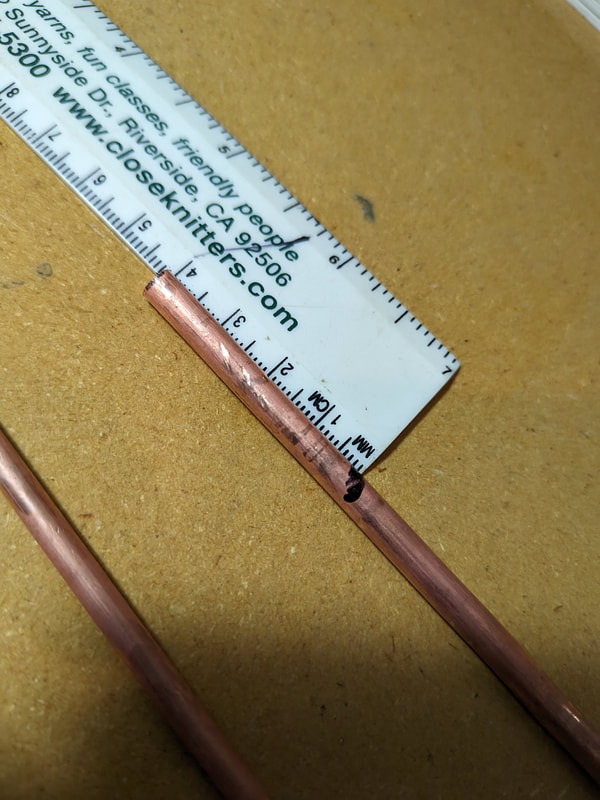

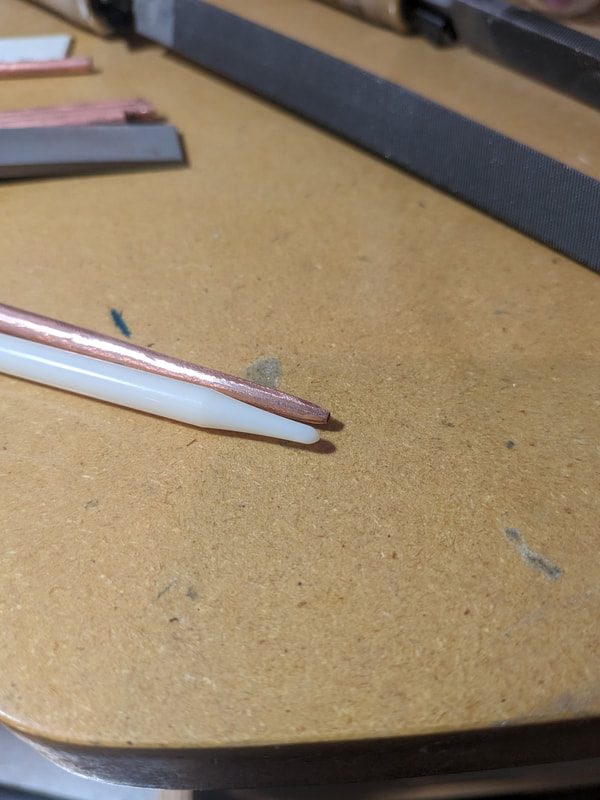

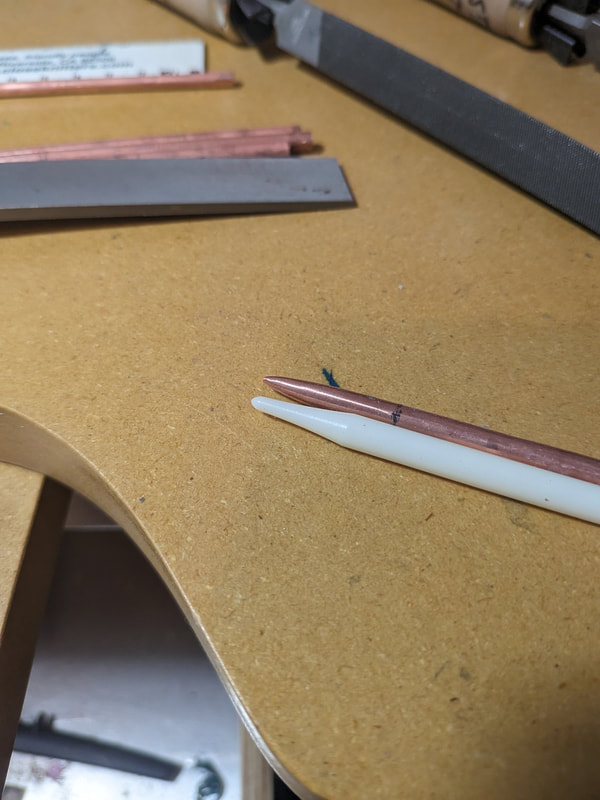

First up - a copper knitting cable needle for a friend. She has one out of sterling silver but the size is a 2.x mm needle and is too small for the baby blanket project she is working on. The project uses a US 13 needle (9mm) which is in between 0 and 00; that's thick wire which is normally used for automotive or solar power battery setup. That gauge is sterling can't be bought from a Jewelry supply house, you have to cast it yourself and then there is the cost which made me turn to copper. Also she will need at least 2 because the baby blanket has 2 sets of cables.

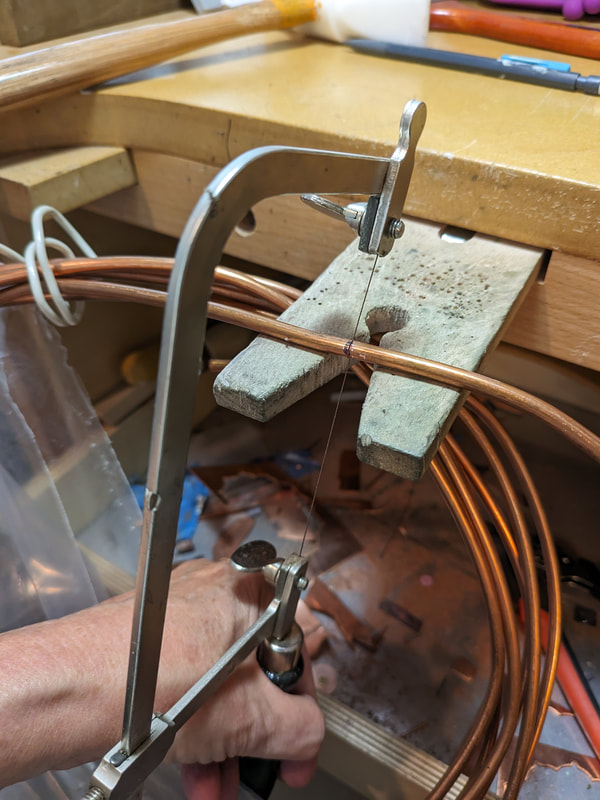

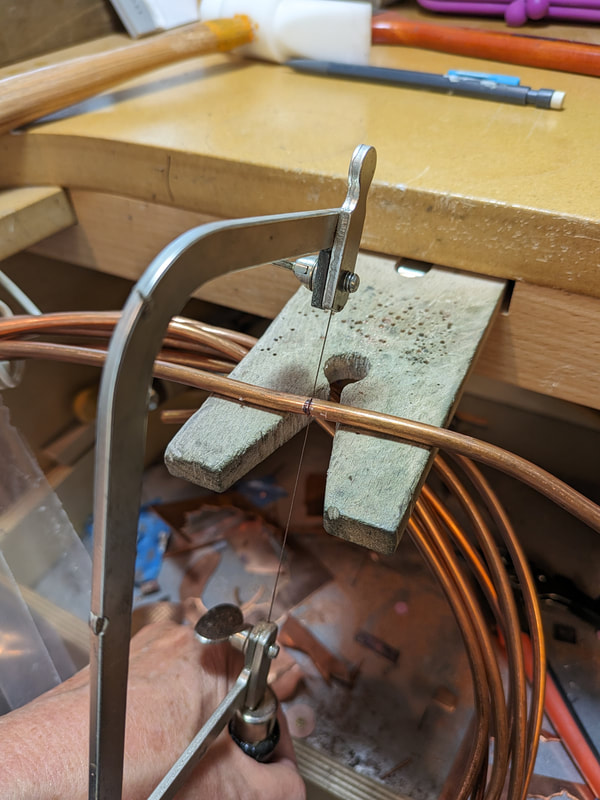

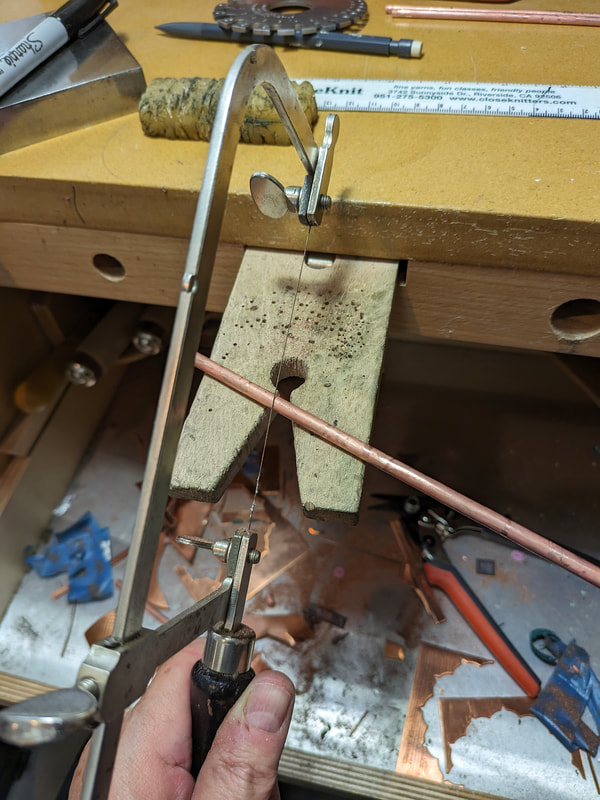

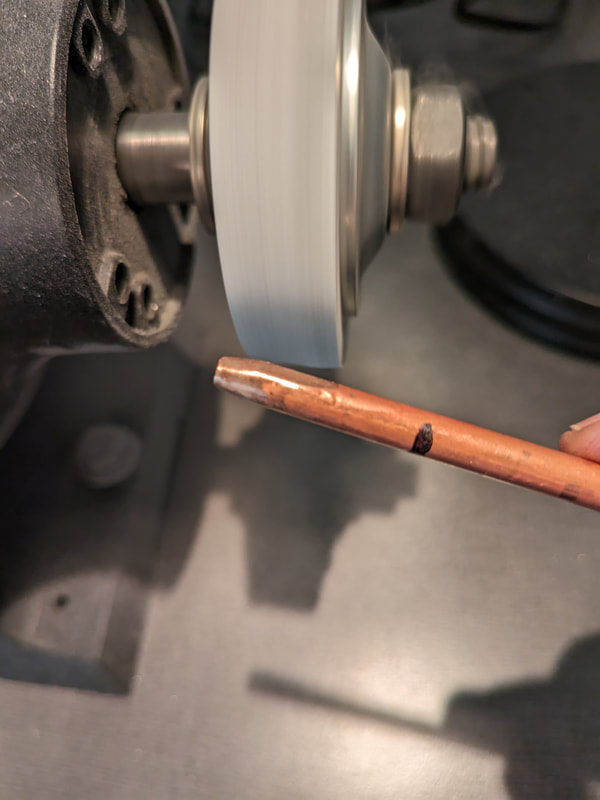

I went into my knitting needle stash and selected a 9, 7, and 6 mm needle and then raided the copper wire bin. I found 2, 3, and 5 gauge wire and cut pieces for the prototype. Then it was time to anneal and straighten followed by filing, grinding, a bit or polishing and lastly more annealing so I could then bend to shape and even more polishing. I only made 1 needle from the thickest wire because it needs some work but from this one those can be determined before I make the final ones.

RSS Feed

RSS Feed