I have now refinished 4 of the 18 hammer heads. Once all of them are done then I will have to sand and clean up the handles and reseat them in the heads. I might have to replace one or two handles are they have a crack and I don't think driving the wedge in further will do any good.

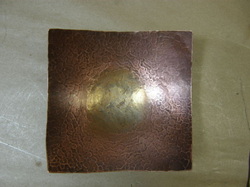

Here are some before, during and after pictures of one of the hammer. You can see they are pretty rusty and full of grime. After taking 280 sand paper to the sides, top and bottom, most of the rust was gone but not in the deep machining grooves - WD-40 will be used to get at that. Then I used 280 to clean up the faces of the hammer. This was difficult as there was some deep pitting and you don't want to ruin the shape (angles and curves) of the faces. After that I took 320, 400 and 600 to the faces as well. This process took 1.5 hours and my hands were red and gray from the sanding. WIth the first phase completed and hands washed, I started with the 9 fine sanding/polishing grits I have to get the faces nice and shiny smooth. This took another 1.5 hours but as you can see in the final pictures, it was worth it.

At this rate, it will take at least another month of weekends to finish all the hammers and the flat planishing hammers will be the hardest.

RSS Feed

RSS Feed