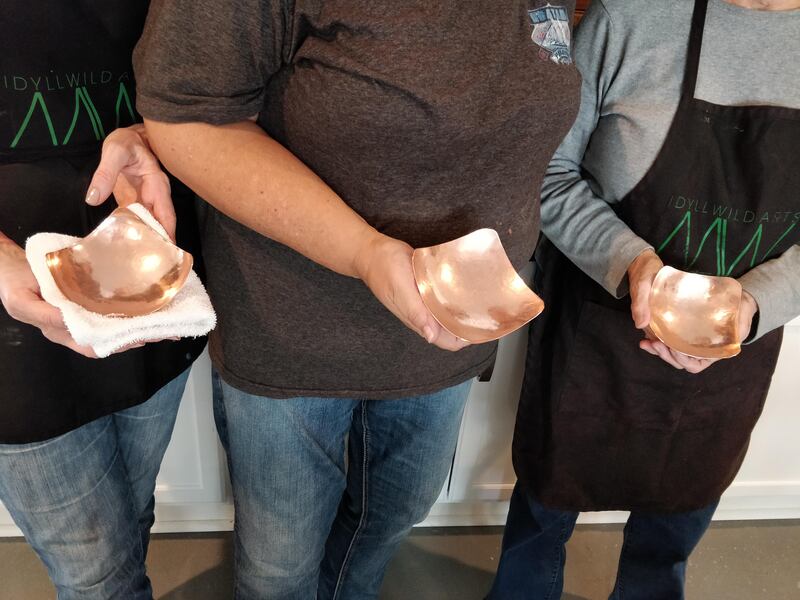

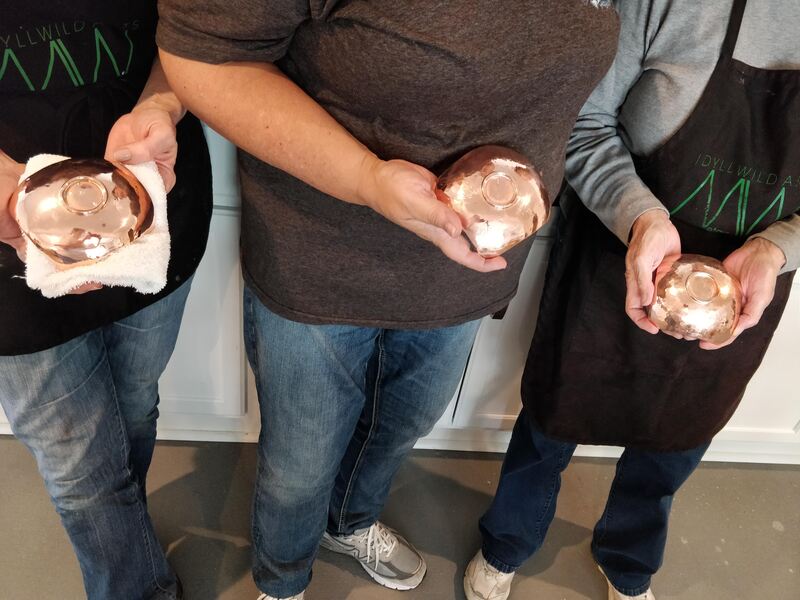

My students were Barbara, Irma, and Nancy. I know Barbara and Irma and Nancy is a friend of Irma's so it was a friendly and relaxed class.

I started the day, before they arrived, annealing, winding, and sawing the ring bases for their bowls. The ladies arrived just before 10 am and into the studio we went! After "The Safety Discussion", the ladies stamped their initials in the center of one side - this would become the bottom/outside of the bowl. Then they learned how to use the jewelers saw to round the corners. We moved on to sanding the edges and how to make sanding sticks. I then demonstrated polishing the copper to soften all edges and to remove the scratches, while the copper was flat so there was less work to do after the bowl was formed. Then came the hammering - sinking into the custom wood forms I have had made over the years, and how to anneal in-between each round of going deeper. When each was happy with the shape and depth of their dish it was time to go to the stake stump and they learned planishing and after that I worked with each of them to solder a ring base on; I did the soldering but they assisted by watching for the flow of the solder and turning the turntable, so I could focus on heating and soldering; they also quenched their dishes and put it in the pickle. Lastly, they did a final polish and their bowls were done.

As we sat around the table, after the class, discussing what they learned they asked what they could learn next!

I guess I need to start planning another class.

RSS Feed

RSS Feed