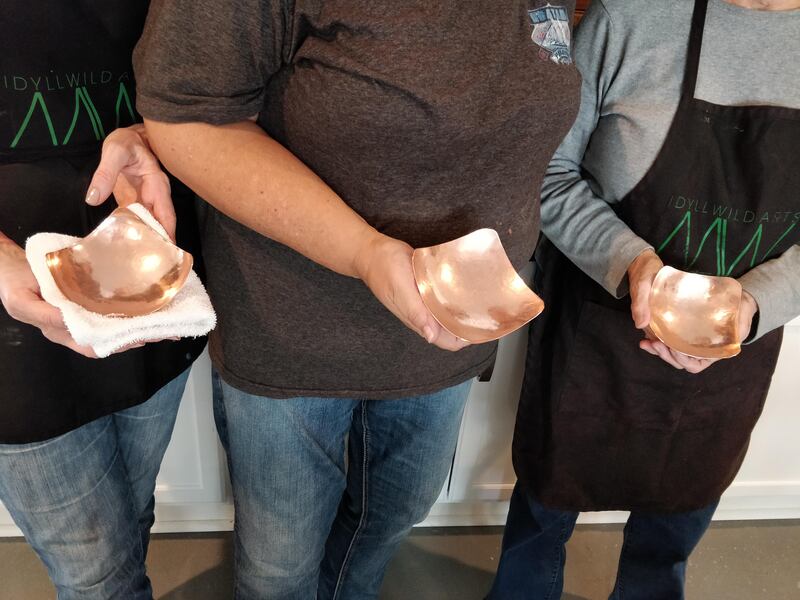

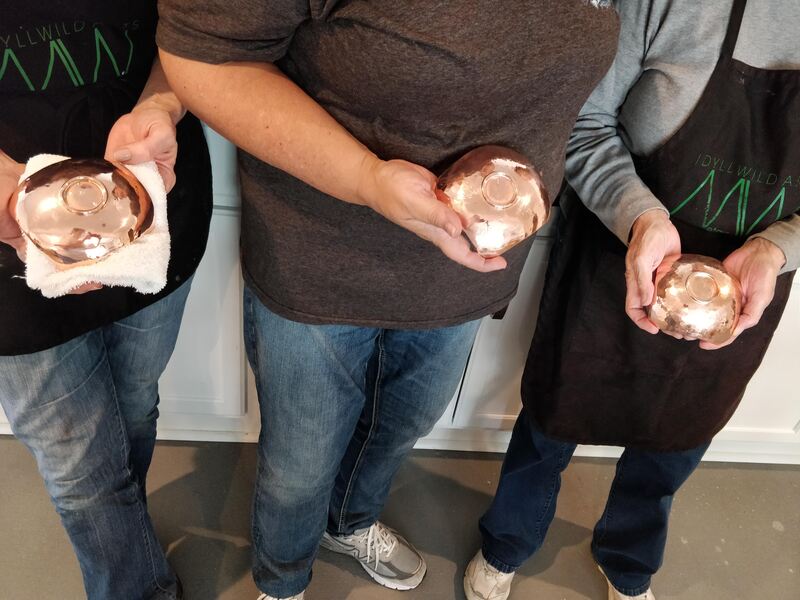

Saturday’s workshop was a Fold Formed Cuff project but the following skills were also covered: using a rolling mill to texturize the metal, stick soldering with hard solder, fold forming basics, and liver of sulfur patina. We started the day at 10:00 am and the cuffs were completed by 5:30 pm.

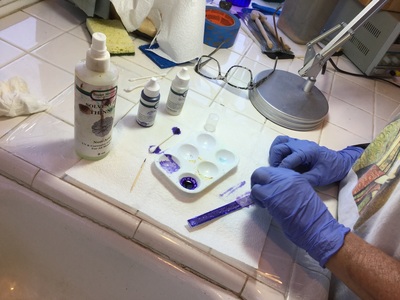

On Sunday we started the day with working on Sherri’s on soldering skills. We started with copper scrap taken from my cut off pile, and I set up for a butt joint between 2 flat pieces; starting with a smaller torch flame that she was comfortable with Sherri quickly saw that the copper never got hot enough to melt the solder. We increased the tip size and had a slightly larger flame; again the solder would not flow. We then increased the flame, a lot, and Sherri was able to solder the two pieces together. The copper went into the pickle and after we cleaned it, I then bent another piece of copper and stood it on the 2 pieces of copper that had been soldered together. This time, using hard solder we put a small ball at each end of the joint and Sherri started to heat everything. With a slight adjustment of the flame (larger) the copper got hot and the solder melted and using the heat of the flame, she was able to pull the solder along from each end and completed filling the joint. Sherri now had a better understanding of how to gauge how much flame/heat is required when working with more metal AND how to practice soldering without doing on a production piece!

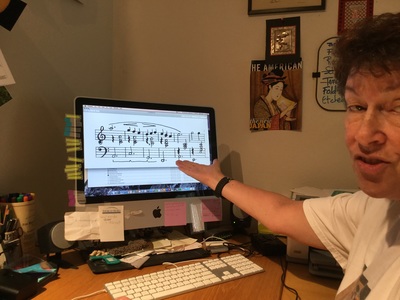

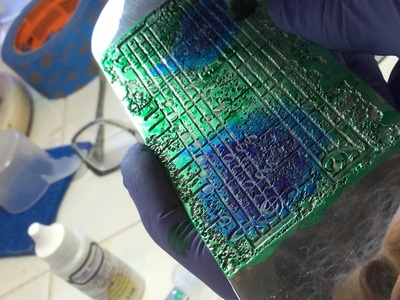

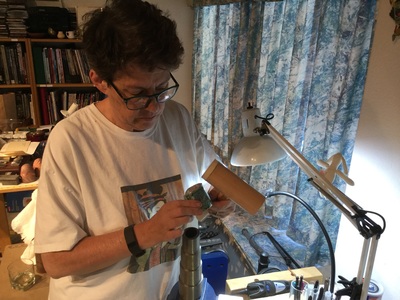

It was now time to start the anticlastic bangle, similar to what I had made last month. We started with brass and then moved to silver. We discussed getting a good seam with hard solder so it does not split during the forming and how to recover if a split does start; forming the bangle with sinusoidal stakes and the correct hammer(s); and cutting the metal length to get a proper sized bangle when done. The bangle was finished by adding some gold ball accents and edge thickening.

RSS Feed

RSS Feed