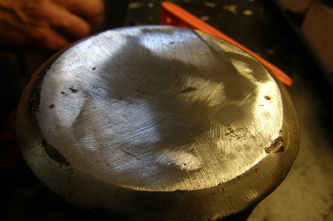

I decided yesterday to start the refinishing of the anvil top. The cone does not have pits like the anvil but will require just a small amount of surface sanding to clean it up. But as you can see from the first two pictures, the top of anvil is badly pitted.

I went out to the garage where my new belt/disk sander is and fired that puppy up with an 80 grit belt to take down the top surface fast.

The first problem was that the edge of the bevel does not blend into the main body, there is a thin step between where the be bevel ends and the main body. So I first round a thin piece of wood to support the body of the anvil thus allowing me to the face to touch the sanding belt evenly. Of course this was not wide enough to support the entire body and so you had to "hold up" the body to keep it against the belt which was vertical. I then tilted the belt back about 30 degrees from vertical so the weight of the anvil was directly slightly downward and away I (we) went. My husband then took a turn at it and if you click on the pictures below, you can see the progress as we removed the pits.

I used a level and laid it across the surface and there are no air gaps between the level and the surface even though the level tells me that the top surface is slightly higher on one edge and this could just be due to the bottom surface not completely square to the to body or parallel to the top. I did check my bench first and it was almost level so it is the anvil. Overall my working surface is flat just not 100% level to what ever surface it is sitting on.

I post these images below, on my Facebook page last night and received some very nice complements including one from Kevin Potter of Potter USA He said "I admire your determination laurie but I am more than happy to polish it for you" and then added "Spend your time making beautiful stuff let me do the dirty work."

Well I have thought long and hard about this. Ok, I only thought about it for 10 hours. And I am very tempted to ship the anvil and the cone mandrel off to him. Just last month he modified some vintage stakes (the tangs) for me so they would fit in his stake holder and did a perfect job.

Back in 2010 I scored a lot of 18 vintage hammer off of eBay but they needed work and I spent almost 2 months of weekends refinishing the faces. Working on the anvil will require at least 10+ hours over several months and using the belt sander for the initial phase of pit removal took 1 1/2 hours alone. The long arduous work is still ahead of me with hand sanding. If Kevin did it, in his shop on his wonderful machines, it would take probably less than 5 hours and it could be as few as 2 or 3 to machine it down just a bit further and then working his way up to put a nice 600+ grit polish on it.

But what would I get out of it besides saving quite a bit of my time?? And there people was the quandary.

Saving Personal Time vs. Personal Satisfaction. What you you do??

But the more I thought about it this morning over my Sunday cuppa; the more I realized I wanted the personal satisfaction of doing this vs. the time savings. I want to say "Look what I refinished" and then be able to show these, and more, pictures off and hear people say WOW.

Even if Kevin did do this job for me we all know people would say WOW. PLUS it would help drive more business to Kevin which is a good thing cause he stays in business and continues to make great tools and equipment and then would be able to refinish other things for you and me when we really, really, really need it.

So, sorry Kevin, I really do appreciate the offer but this time, this is one is mine to do. Next weekend I will take a few hours and work my way through 100 grit. Each weekend I will then progress further up from 120, 220, 300 and when I reach 600 grit THEN I will decide if I want to spend more time for the extra WOW factor.

RSS Feed

RSS Feed