I also learned to use a knife edge dowel during fold forming when you need to pry your folds open.

But over time, the dowel ends get all mushed and they start to break apart. This is not good cause you are always making new ones.

Being the engineer that I am, I knew that a PLASTIC (and I use that term loosely) tool would last much longer. I have been experimenting with various materials and have found Acetal (a.k.a Delrin) to be the best material as it is not brittle, it won't bend when hit, even on the smallest diameter tools, and it holds up really well over time.

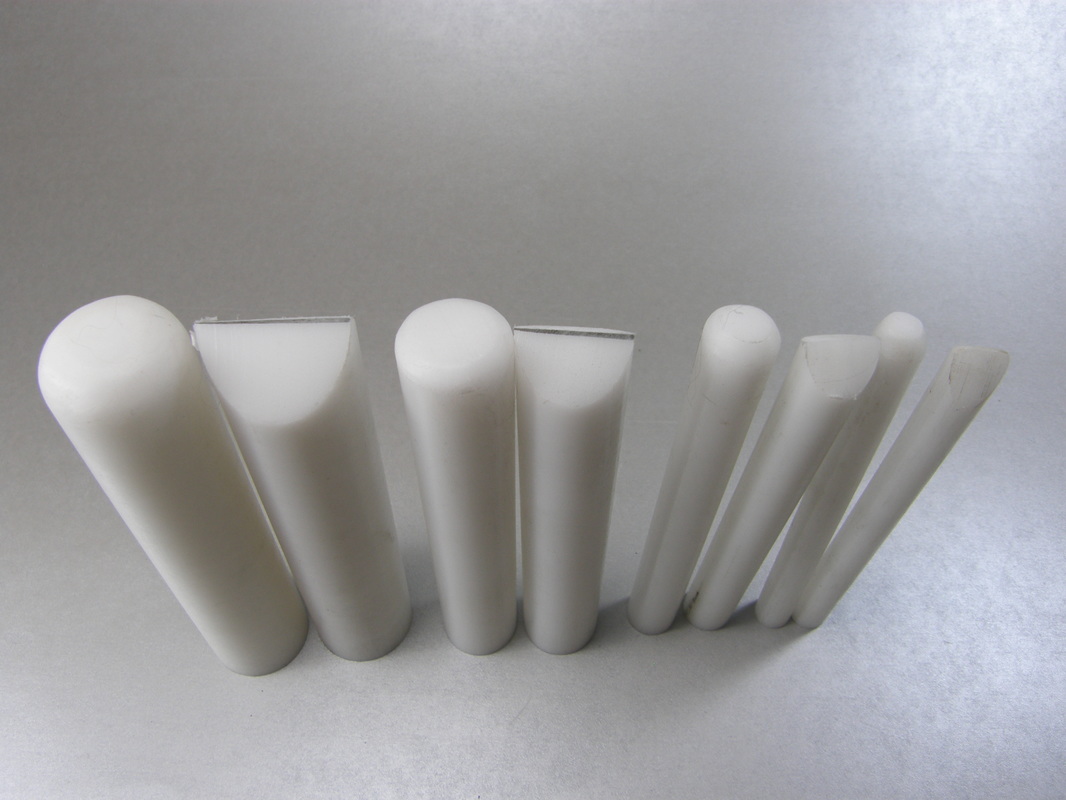

I made my first 2 tools over 3 years ago and my set now has 12 tools - some are domed, some flat, some knife edge and all are different diameters depending on what I need for my projects. When I started to teach, I would bring my set to class for the students to use and of course over time, they wanted a set too.

Last year I made 8 sets and sold them all before I even had a chance to put them up for sale in my store. Making these 8 sets took time as I had to not only cut the rods to length but then shape them. I have since done more research and found a new supplier who will cut the rod stock to length; which is a big time saver.

So, here they are - 8 acetal tools: 2 different working faces in 4 different diameters with a length of 4 - 4.5 inches.

With time, I will add domed tools and some other sizes but these should get you started.

Use this link to buy a set for you or your metalsmith friends!

RSS Feed

RSS Feed