Pat Downing was there as our leader and I met many new folks who also hung out at the forge. The big surprise was that one of the people there was also at the same session of Haystack last summer. He was in the blacksmith group (I was in metals) but we did have several conversations while we were there and it was nice to talk and catch up on what we have been doing since then.

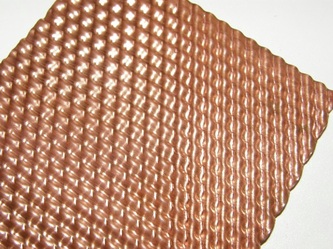

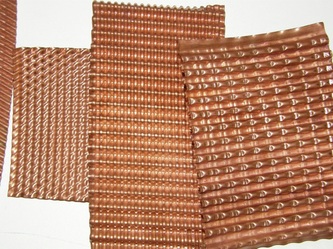

Here are pictures of what happened.

RSS Feed

RSS Feed