My plan was to put it in the rolling toolbox I inherited from the Shop Elf but first I had to clean it. It was empty it; vacuum out the dust and other schmutz; then start the tooling inventory.

IT TOOK THREE DAYS.

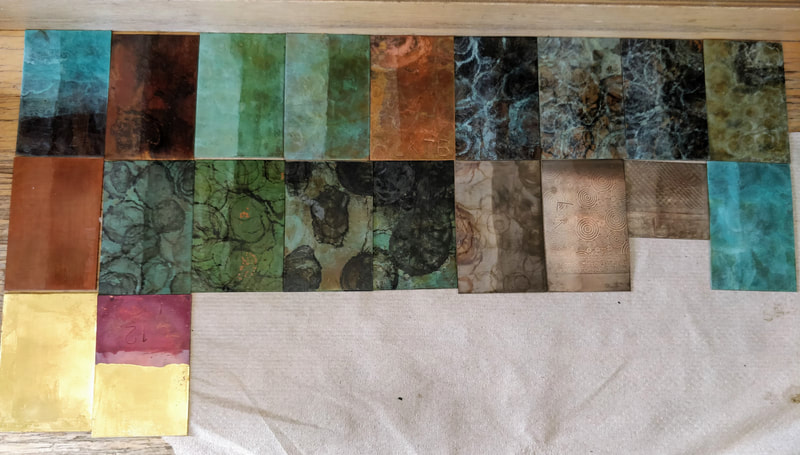

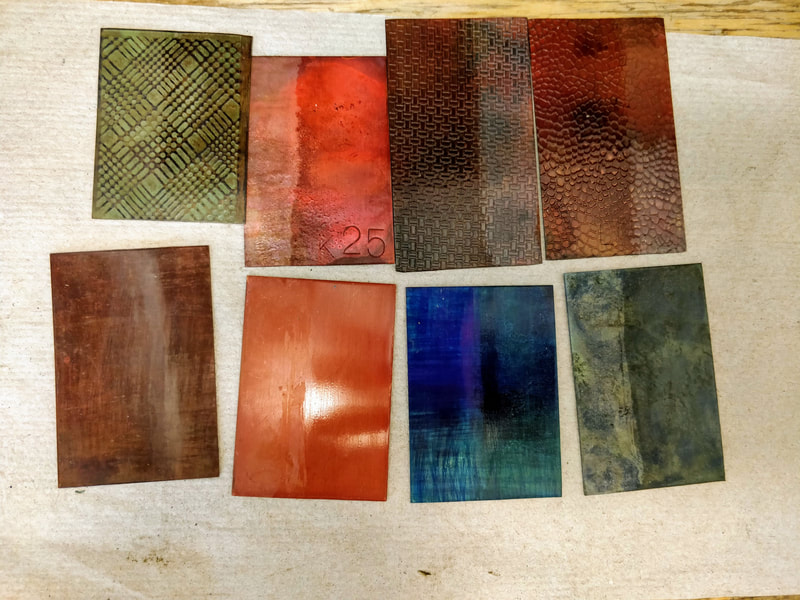

I organized the tooling by type on the counter and would carry a few items to my desk where I could verify it's existance in the Tracker. Next was to use a vibrating engraving pen and mark it. I then put it in a drawer which was labeled with the tooling type.

I had some tooling that I had no sku number for nor were they marked so I went to the hive mind in the PotterUSA Facebook group for assistance and they came through.

Everything is now in the toolbox and I just have a few things to put away today and I AM DONE with this task and organizing the studio; I CAN NOW PLAY IN HERE

RSS Feed

RSS Feed